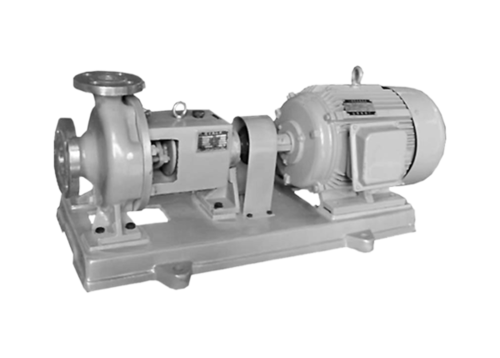

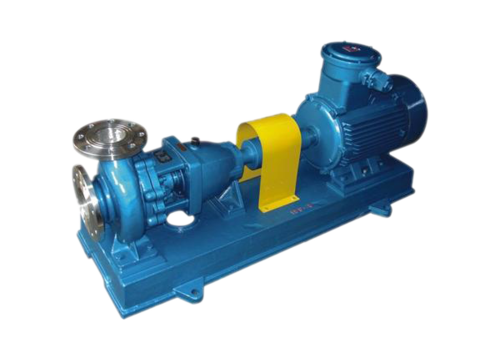

KBS type single-stage double-suction medium-open pump

Keywords:

Classification:

Inquiry Hotline:

KBS type single-stage double-suction medium-open pump

I. Overview

KBS type pump is a new generation of high performance single-stage double-suction center-open centrifugal pump. The pump selects excellent hydraulic model, so that the efficiency of the pump is 2-3% higher than the same type of pump, which greatly reduces the running cost of the pump and increases the vacuum height by 1-3 meters, thus reducing the civil construction investment and extending the service life. The water inlet and outlet are in the same straight line, and the same rotor can run in reverse. The support spacing between the two ends of the pump is short, the pump runs stably, the vibration noise is small, and the speed can be properly increased to run, so that the pump can adapt to a wider range. The pump body part can be installed vertically or horizontally according to the change of use. It is mainly used in waterworks, air-conditioning circulating water, heating pipeline system, building water supply, irrigation, drainage pumping station, power plant, industrial water supply system, fire-fighting system, ship industry, mine water supply and drainage, etc. It is a comprehensive replacement product of SH, S, SA, SLA, SAP type medium open double suction pump.

II. Meaning of model

KBS 250 - 480 A - L - R(M、F) - J

| KBS | — | Kun pump new single-stage double-suction center-open pump |

| 250 | — | Water pump outlet diameter |

| 480 | — | Impeller diameter |

| A | — | Impeller first cut |

| L | — | Vertical installation |

| R | — | Hot water type |

| M | — | Wear-resistant type |

| F | — | Corrosion-resistant type |

| J | — | Shaft seal is mechanical seal |

III. Main Technical Parameters

Pump outlet diameter: DN=80 ~ 800mm

Flow rate: Q=22 ~ 11660m3/h

Head: H=7 ~ 200m

Working temperature: T=-20℃~105℃ (KBS type) =-60℃~200℃ (KBS-R type)

Solid particles: ≤80mg/l

Allowable working pressure: ≤2.5Mpa (KBS type) ≤4Mpa (KBS-R type)

IV. Structure Description

1、Structure

The inlet and outlet are in the same straight line, the same rotor can run in reverse, the support spacing between the two ends of the pump is short, the pump runs stably, the vibration noise is small, and the speed can be appropriately increased to run, so that the pump can adapt to a wider range. The water pump can adopt intermediate support, thickened pump body, seal cooling, bearing thin oil lubrication, etc., so that the water pump can be applied to the operating occasion of up to 200℃, especially suitable for the requirements of heating pipeline network use. The pump body part can be installed vertically or horizontally according to the change of using conditions, and the seal can adopt mechanical seal or packing seal.

2、Technical advantages

● The support distance between the two ends of the pump is short, so that the pump runs stably and the vibration and noise are small.

● The inlet and outlet are in the same straight line, which makes the pipeline arrangement simple, convenient and beautiful.

● The same rotor can run in reverse, which reduces the risk of pump damage caused by water hammer.

The unique high temperature design, middle support, thickened pump body, seal cooling, and thin oil lubrication of the bearings make the pump suitable for operation at temperatures up to 200°C. It is especially suitable for use in heat supply networks.

The pump body can be installed vertically or horizontally according to the change of use, and the seal can be mechanical seal or packing seal.

The appearance of the pump is industrialized and has clear lines, which meets modern aesthetics.

3. Cost advantages:

Excellent hydraulic model is selected, which makes the pump efficiency 2-3% higher than the same type of pump and greatly reduces the operating cost of the pump.

The vacuum height is increased by 1-3 meters, thus reducing the civil construction investment and extending the service life.

Imported bearings are selected and parts materials can be chosen according to user requirements, which makes the pump adaptable to various field operating conditions and greatly reduces maintenance costs.

4、Maintenance advantages:

Collective mechanical seal, replacing mechanical seal becomes an easy and simple job.

Application of elastic pre-stress assembly, rotor parts are easy and quick to assemble and disassemble.

No need to adjust various clearances when assembling.

V. Pump structure diagram

1、Pump body 2、Impeller 3、Pump cover 4、Water flushing tube parts 5、Sealing ring

6、Pipe plug 7、O-ring 8、Sealing body 9、Sealing gland or packing gland 10、Water retaining ring

11、Bearing gland 12、Bearing body 13、Shaft 14、Skeleton oil seal 15、Flexible retaining ring

16、Bearing retaining ring 17、Sleeve 18、Mechanical seal or packing seal 19、Bearing sleeve 20、Bearing

21、Bearing washer 22、Butterfly spring 23、Locking nut

Ⅵ.the main parts of the material table

| Part Name | Material Name | Code Name |

| Pump Casing | Grey cast iron | HT250 |

| Ductile Iron | QT400-18 | |

| Cast steel | ZG230-450 | |

| Impeller | Bronze | ZCuSn10Pb1 |

| Grey cast iron | HT250 | |

| Silicon brass | ZCuZn16Si4 | |

| Stainless Steel | ZC0Cr18Ni12Mo2Ti | |

| Shaft | Stainless Steel | 2Cr13 |

| Carbon Steel | 45 | |

| Pump body sealing ring | Bronze | ZCuSn5Pb5Zn5 |

| Grey cast iron | HT250 | |

| Silicon brass | ZCuZn16Si4 | |

| Stainless Steel | ZC0Cr18Ni9Ti |

Ⅶ. performance parameters table

| Model | Flow | Head | Rotational Speed | Efficiency | Motor power | Necessary | Quality | |

| Q | H | n | η | Cavitation allowance | m | |||

| m3/h | m | r/min | % | kW | m | kg | ||

| 80-210 | 50.1 | 16 | 1450 | 75 | 5.5 | 1.6 | 278 | |

| 83.5 | 13.8 | 82 | ||||||

| 100.2 | 12.4 | 80 | ||||||

| A | 46.3 | 13.8 | 74 | 4 | ||||

| 77.2 | 11.8 | 81 | ||||||

| 92.6 | 10.5 | 80 | ||||||

| B | 42 | 11.8 | 72 | 3 | ||||

| 70.4 | 9.8 | 80.5 | ||||||

| 84 | 9 | 78 | ||||||

| C | 38.6 | 10 | 72 | 3 | ||||

| 64.4 | 8.2 | 78 | ||||||

| 77.3 | 7 | 76 | ||||||

| 98.7 | 64.8 | 2900 | 75 | 37 | 4.5 | 278 | ||

| 164.5 | 55 | 82 | ||||||

| 197.4 | 49 | 80.5 | ||||||

| A | 97.7 | 56 | 74 | 30 | ||||

| 152.9 | 47.5 | 81 | ||||||

| 183.5 | 42 | 80 | ||||||

| B | 83 | 47.5 | 73 | 30 | ||||

| 138.5 | 39 | 80.5 | ||||||

| 166.2 | 36 | 79 | ||||||

| 80-210 | C | 77.4 | 41 | 2900 | 72 | 22 | 4.5 | 278 |

| 128.4 | 33.5 | 77.8 | ||||||

| 154 | 30 | 76 | ||||||

| 80-270 | 60.5 | 25.8 | 1450 | 73 | 11 | 2.3 | 293 | |

| 100.8 | 22.8 | 78.5 | ||||||

| 121 | 20.5 | 76 | ||||||

| A | 57.6 | 22.4 | 72 | 11 | ||||

| 96 | 19.3 | 77 | ||||||

| 115.2 | 17.4 | 74 | ||||||

| B | 52.9 | 18.8 | 70 | 7.5 | ||||

| 88.1 | 16 | 76 | ||||||

| 105.7 | 14.3 | 74 | ||||||

| C | 47.6 | 15.7 | 68 | 5.5 | ||||

| 79.4 | 13 | 75 | ||||||

| 95.3 | 11.6 | 73 | ||||||

| 124.8 | 102.5 | 2900 | 73 | 75 | 6.3 | 293 | ||

| 208 | 90 | 78.5 | ||||||

| 249.6 | 79 | 75.5 | ||||||

| A | 115.5 | 90 | 72 | 75 | ||||

| 192.4 | 77 | 77.5 | ||||||

| 230.9 | 68 | 75.5 | ||||||

| B | 104.8 | 75 | 2900 | 72.5 | 55 | 6.3 | 293 | |

| 174.7 | 63.5 | 76 | ||||||

| 209.6 | 57.5 | 74 | ||||||

| C | 93 | 63 | 71 | 37 | ||||

| 155 | 53 | 75 | ||||||

| 186 | 48 | 74 | ||||||

| 80-370 | 67 | 42.5 | 1450 | 68 | 22 | 2.3 | 308 | |

| 111.6 | 38.8 | 75 | ||||||

| 134 | 34.5 | 73 | ||||||

| A | 63.6 | 36.5 | 66 | 15 | ||||

| 105.5 | 33 | 72 | ||||||

| 126.6 | 28 | 69 | ||||||

| B | 52.8 | 30 | 65 | 15 | ||||

| 96.3 | 26.5 | 70 | ||||||

| 115.6 | 23 | 66 | ||||||

| C | 52.3 | 25 | 63 | 11 | ||||

| 87.1 | 22.5 | 67 | ||||||

| 104.5 | 18 | 62 | ||||||

| 100-250 | 90.7 | 22 | 1450 | 77 | 11 | 2.4 | 315 | |

| 151.2 | 18.5 | 82 | ||||||

| 181.4 | 16 | 80.5 | ||||||

| A | 29.2 | 18.7 | 73 | 11 | ||||

| 132.9 | 15.8 | 81 | ||||||

| 159.5 | 14.2 | 80 | ||||||

| B | 73.7 | 16 | 72 | 7.5 | ||||

| 122.9 | 13.5 | 79 | ||||||

| 147.5 | 12 | 78 | ||||||

| C | 69.5 | 13.5 | 72 | 7.5 | ||||

| 115.9 | 11 | 77.5 | ||||||

| 139 | 10 | 76 | ||||||

| 173.4 | 87 | 2900 | 76 | 90 | 7.1 | 315 | ||

| 289 | 75 | 82.5 | ||||||

| 346.8 | 67 | 81.5 | ||||||

| A | 159 | 75 | 74 | 75 | ||||

| 264.9 | 63 | 80.5 | ||||||

| 317.8 | 57 | 80 | ||||||

| B | 144 | 65 | 73 | 55 | ||||

| 240.5 | 52 | 79 | ||||||

| 288.6 | 48 | 80 | ||||||

| C | 134 | 53 | 71 | 45 | ||||

| 223.4 | 47 | 78 | ||||||

| 268 | 41 | 76 | ||||||

| 100-310 | 105.8 | 36.3 | 1450 | 73 | 22 | 2.6 | 338 | |

| 176.4 | 31.2 | 80 | ||||||

| 211.7 | 26.8 | 77 | ||||||

| A | 103.6 | 31 | 75 | 18.5 | ||||

| 172.6 | 26 | 79.6 | ||||||

| 207 | 18.3 | 76 | ||||||

| B | 94.5 | 26.2 | 72 | 15 | ||||

| 157.5 | 22.5 | 79.3 | ||||||

| 189 | 15 | 75 | ||||||

| C | 85.7 | 22 | 74 | 11 | ||||

| 142.8 | 18.5 | 79 | ||||||

| 171.4 | 15 | 74 | ||||||

| 220 | 145 | 2900 | 74 | 185 | 11 | 338 | ||

| 349 | 126 | 80 | ||||||

| 441.6 | 107 | 77 | ||||||

| A | 245 | 120 | 77 | 132 | ||||

| 341.6 | 106 | 79.6 | ||||||

| 410 | 90 | 76 | ||||||

| B | 205 | 104 | 73 | 110 | ||||

| 314 | 87 | 79.3 | ||||||

| 377.8 | 78 | 76 | ||||||

| C | 147 | 90 | 70 | 90 | ||||

| 245.4 | 78 | 79 | ||||||

| 294.5 | 66 | 75 | ||||||

| 100-375 | 113.4 | 61 | 1450 | 68 | 45 | 2.5 | 368 | |

| 189 | 51 | 76.5 | ||||||

| 226.8 | 42 | 72 | ||||||

| A | 102.4 | 51 | 65 | 30 | ||||

| 170.6 | 44 | 74 | ||||||

| 204.7 | 36 | 70 | ||||||

| B | 91.8 | 44 | 63 | 30 | ||||

| 153 | 38 | 72 | ||||||

| 183.6 | 33 | 69 | ||||||

| C | 85 | 34 | 63 | 18.5 | ||||

| 141.6 | 29 | 69 | ||||||

| 170 | 24 | 64 | ||||||

| 125-230 | 155.6 | 19 | 1450 | 75.5 | 18.5 | 1.8 | 375 | |

| 262.8 | 15 | 85.5 | ||||||

| 329.5 | 12 | 82 | ||||||

| A | 155.6 | 16.2 | 73 | 15 | ||||

| 262.8 | 12.5 | 84.5 | ||||||

| 328.9 | 9 | 82 | ||||||

| B | 139.4 | 14 | 73 | 15 | ||||

| 232.4 | 11 | 82.5 | ||||||

| 278.9 | 8.5 | 75 | ||||||

| C | 118.8 | 12.5 | 70 | 11 | ||||

| 198 | 8.5 | 77.5 | ||||||

| 237.6 | 7.3 | 74 | ||||||

| 320 | 75 | 2900 | 76 | 110 | 6.8 | 375 | ||

| 533.5 | 60 | 85.5 | ||||||

| 640 | 50 | 83 | ||||||

| A | 298 | 66 | 74 | 90 | ||||

| 496.7 | 52 | 84 | ||||||

| 596 | 42 | 80 | ||||||

| B | 272.6 | 57 | 73.2 | 75 | ||||

| 454.3 | 43.5 | 82 | ||||||

| 545.2 | 34 | 78 | ||||||

| C | 247 | 48 | 70 | 75 | ||||

| 411.6 | 34 | 77 | ||||||

| 494 | 27 | 75 | ||||||

| 125-290 | 162 | 31.3 | 1450 | 76 | 30 | 1.9 | 413 | |

| 270 | 27 | 84 | ||||||

| 324 | 23.4 | 81 | ||||||

| A | 146.2 | 26.5 | 74 | 22 | ||||

| 243.7 | 22 | 82 | ||||||

| 292.4 | 19.3 | 80 | ||||||

| B | 132.2 | 22 | 1450 | 73 | 18.5 | 1.9 | 413 | |

| 220.5 | 18 | 80 | ||||||

| 292.4 | 16 | 78 | ||||||

| C | 117.5 | 18.5 | 70 | 15 | ||||

| 195.8 | 14.2 | 78 | ||||||

| 235 | 12.3 | 75 | ||||||

| 321.3 | 125 | 2900 | 77 | 200 | 7.6 | 413 | ||

| 535.5 | 108 | 84 | ||||||

| 642.6 | 95 | 81 | ||||||

| A | 290 | 105 | 75 | 185 | ||||

| 400 | 98 | 80 | ||||||

| 580 | 77 | 80 | ||||||

| B | 262.3 | 74 | 73 | 132 | ||||

| 437.2 | 57 | 80 | ||||||

| 524.6 | 45 | 78 | ||||||

| C | 233.4 | 74 | 72 | 90 | ||||

| 389 | 57 | 78 | ||||||

| 466.8 | 43 | 75 | ||||||

| 125-365 | 187.9 | 52 | 1450 | 76 | 75 | 2.1 | 450 | |

| 313.2 | 46.2 | 84 | ||||||

| 375.8 | 42 | 81 | ||||||

| A | 169.7 | 43.5 | 74 | 45 | ||||

| 282.8 | 39 | 83 | ||||||

| 399.4 | 36 | 80 | ||||||

| B | 152.5 | 35.5 | 73 | 37 | ||||

| 254.2 | 31.5 | 82 | ||||||

| 305 | 29 | 79 | ||||||

| C | 133.1 | 27 | 70 | 30 | ||||

| 211.9 | 24 | 80 | ||||||

| 266.3 | 22 | 78 | ||||||

| 125-500 | 194.6 | 84 | 1450 | 75 | 110 | 2.3 | 503 | |

| 324 | 76 | 82 | ||||||

| 388.8 | 70 | 80 | ||||||

| A | 168.5 | 73 | 72 | 90 | ||||

| 280.8 | 67.5 | 80 | ||||||

| 388.8 | 62 | 78 | ||||||

| B | 146.9 | 62.3 | 70 | 75 | ||||

| 244.8 | 57 | 78 | ||||||

| 293.8 | 53 | 76 | ||||||

| C | 129.6 | 53 | 67 | 45 | ||||

| 216 | 48 | 76 | ||||||

| 259.2 | 44 | 72 | ||||||

| 150-290 | 266.1 | 26.5 | 1450 | 76 | 37 | 2.4 | 521 | |

| 443.5 | 21 | 86 | ||||||

| 532.2 | 18 | 82 | ||||||

| A | 246.4 | 23 | 75 | 30 | ||||

| 410.6 | 18 | 85 | ||||||

| 492.7 | 14.8 | 80 | ||||||

| B | 220 | 19.6 | 75 | 22 | ||||

| 367 | 15.5 | 83 | ||||||

| 440 | 13 | 80 | ||||||

| C | 203 | 16 | 70 | 18.5 | ||||

| 338.2 | 11.7 | 77 | ||||||

| 405.8 | 9.5 | 75 | ||||||

| 150-360 | 268.5 | 44 | 1450 | 76 | 75 | 3 | 539 | |

| 447.5 | 38 | 85 | ||||||

| 537 | 33 | 82 | ||||||

| A | 242.5 | 37.3 | 75 | 55 | ||||

| 400 | 32 | 80 | ||||||

| 485 | 27 | 80 | ||||||

| B | 217.8 | 31.5 | 74 | 37 | ||||

| 363 | 25.5 | 81 | ||||||

| 435.6 | 22 | 78 | ||||||

| C | 194.8 | 26 | 72 | 30 | ||||

| 324.7 | 20.5 | 78 | ||||||

| 389.6 | 16.5 | 76 | ||||||

| 150-450 | 309.3 | 74 | 1450 | 74 | 132 | 3 | 654 | |

| 515.5 | 66 | 82 | ||||||

| 618.6 | 60 | 79 | ||||||

| A | 281 | 62.5 | 73 | 110 | ||||

| 468.4 | 54.5 | 81 | ||||||

| 562.1 | 47.5 | 78 | ||||||

| B | 251 | 51 | 71 | 75 | ||||

| 418.5 | 43.5 | 80 | ||||||

| 502.2 | 36 | 78 | ||||||

| C | 275.2 | 41 | 70 | 55 | ||||

| 375.4 | 35.5 | 78.5 | ||||||

| 450.5 | 30 | 75 | ||||||

| 150-605 | 350.4 | 117 | 1450 | 74 | 250 | 3.7 | 969 | |

| 584 | 105 | 81 | ||||||

| 700.8 | 96 | 78 | ||||||

| A | 321.7 | 102 | 72 | 200 | ||||

| 536.2 | 91 | 80 | ||||||

| 643.4 | 80.5 | 76 | ||||||

| B | 296.2 | 87 | 70 | 160 | ||||

| 493.6 | 77 | 78.5 | ||||||

| 592.3 | 69 | 75 | ||||||

| C | 270 | 73 | 69 | 132 | ||||

| 450 | 62.5 | 77 | ||||||

| 540 | 55 | 73 | ||||||

| 200-320 | 407.3 | 37 | 1450 | 77 | 75 | 3.3 | 675 | |

| 695.5 | 30 | 87 | ||||||

| 834.6 | 25 | 84.5 | ||||||

| A | 384.7 | 33 | 76 | 75 | ||||

| 641.2 | 25.5 | 86.5 | ||||||

| 769.4 | 21 | 84 | ||||||

| B | 351 | 28 | 74 | 55 | ||||

| 585 | 21.3 | 85 | ||||||

| 702 | 17 | 80 | ||||||

| C | 318 | 23 | 72 | 37 | ||||

| 530 | 17.5 | 79 | ||||||

| 636 | 15 | 78 | ||||||

| 200-420 | 426 | 60 | 1450 | 78 | 132 | 3.8 | 776 | |

| 710 | 52 | 86 | ||||||

| 852 | 46 | 84 | ||||||

| A | 385.1 | 51 | 77 | 110 | ||||

| 641.9 | 42.5 | 84.5 | ||||||

| 770.3 | 37 | 82 | ||||||

| B | 352 | 43 | 1450 | 76 | 90 | 3.8 | 776 | |

| 586.6 | 35.5 | 83 | ||||||

| 704 | 28 | 80 | ||||||

| C | 325.4 | 36 | 74 | 75 | ||||

| 525.6 | 28.5 | 81 | ||||||

| 630.7 | 22.5 | 79 | ||||||

| 200-520 | 490.8 | 103 | 1450 | 76 | 280 | 3.5 | 1260 | |

| 818 | 91 | 84 | ||||||

| 981.6 | 83 | 82 | ||||||

| A | 450 | 87 | 75 | 250 | ||||

| 750 | 76.5 | 83 | ||||||

| 900 | 70 | 81 | ||||||

| B | 412.7 | 72 | 74 | 185 | ||||

| 687.9 |

Related Products Product Inquiry

| |||||||