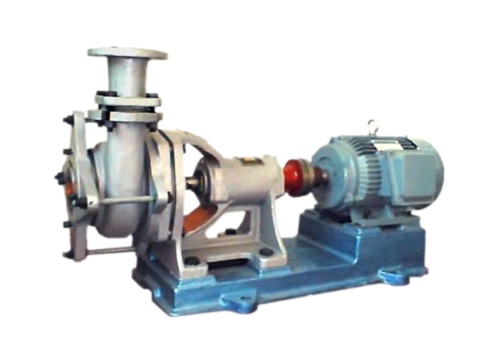

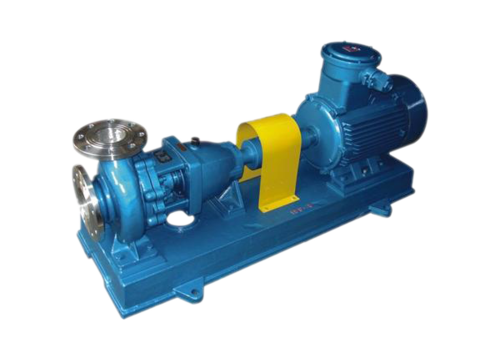

ZDS slurry pump

Keywords:

Classification:

Inquiry Hotline:

ZDS slurry pump

I. Overview

ZDS slurry pump adopts the advanced two-phase flow design theory and method, which greatly improves the hydraulic efficiency, cavitation performance and service life of the pump, especially the efficiency of conveying slurry is higher than that of conveying clear water. This series of pumps has the advantages of compact structure, small volume, light weight, stable operation, low noise, wide application, strong adaptability, good generalization and interchangeability, convenient maintenance, disassembly and assembly, and long service life. It can be widely used in metallurgy, mining, coal, electric power, food, paper making, building materials, transportation, water conservancy and urban sewage departments to transport medium containing suspended solid particles (such as concentrate, tailings, ash, slime, mud and mortar), with an average energy saving of 10-25% compared with the old sand pump.

II. Meaning of model

50 ZDS 30 — 20

| 50 | — |

Discharge diameter mm |

| Z | — |

Slurry pump |

| D | — |

Low head (high head is represented by G) |

| S | — |

Inner shell materials (S for metal, J for rubber, |

|

and T for others) |

||

| 30 | — |

Flow rate (m3/h) |

| 20 | — | Head (m) |

Ⅲ、Performance parameters table

| Model | Flow | Head | Rotational Speed |

Efficiency |

Necessary cavitation |

Maximum conveying particle size | Specific gravity of pulp | Motor power |

| Q | H | n | η | Residuals | γ | P | ||

| m3/h | m | r/min | % | m | mm | kg/m3 | kW | |

| 40ZDS15-15 | 15 | 15 | 2840 | 55 | 3.4 | 8 | γ≤1540 | 2.2 |

| 2870 | 1540<γ≤1640 | 3 | ||||||

| 40ZDS15-25 | 15 | 25 | 2890 | 48 | 3 | 6 | γ≤1320 | 4 |

| 2900 | 1320<γ≤1640 | 5.5 | ||||||

| 40ZDS15-40 | 15 | 40 | 2900 | 41 | 3.5 | 8 | γ≤1550 | 7.5 |

| 2930 | 1550<γ≤1640 | 11 | ||||||

| 50ZDS30-20 | 30 | 20 | 2900 | 56 | 3.5 | 14 | γ≤1560 | 5.5 |

| 1560<γ≤1640 | 7.5 | |||||||

| 50ZDS30-30 | 30 | 30 | 2900 | 51 | 3.5 | 12 | γ≤1290 | 7.5 |

| 2930 | 1290<γ≤1640 | 11 | ||||||

| 50ZDS30-45 | 30 | 45 | 2930 | 55 | 3.5 | 14 | γ≤1200 | 11 |

| 1200<γ≤1640 | 15 | |||||||

| 50ZGS36-60 | 36 | 60 | 2940 | 47 | 3.5 | 12 | γ≤1460 | 22 |

| 2950 | 1460<γ≤1640 | 30 | ||||||

| 65ZDS45-21 | 45 | 21 | 1440 | 56 | 3.5 | 16 | γ≤1350 | 7.5 |

| 1460 | 1350<γ≤1640 | 11 | ||||||

| 65ZDS45-30 | 45 | 30 | 1460 | 52 | 3.5 | 11 | γ≤1300 | 11 |

| 1300<γ≤1640 | 15 | |||||||

| 65ZDS50-40 | 50 | 40 | 1470 | 56 | 3.5 | 18 | γ≤1380 | 18.5 |

| 1380<γ≤1640 | 22 | |||||||

| 65ZGS54-60 | 54 | 60 | 1470 | 44 | 3.5 | 18 | γ≤1250 | 30 |

| 1480 | 1250<γ≤1530 | 37 | ||||||

| 80ZDS80-21 | 80 | 21 | 1460 | 65 | 4 | 20 | γ≤1300 | 11 |

| 1300<γ≤1640 | 15 | |||||||

| 80ZDS80-30 | 80 | 30 | 1470 | 60 | 4 | 18 | γ≤1400 | 18.5 |

| 1400<γ≤1640 | 22 | |||||||

| 80ZDS80-40 | 80 | 40 | 1470 | 56 | 4 | 23 | γ≤1200 | 22 |

| 1200<γ≤1640 | 30 | |||||||

| 100ZDS100-20 | 100 | 20 | 1460 | 66 | 3.5 | 25 | γ≤1500 | 15 |

| 1470 | 1500<γ≤1640 | 18.5 | ||||||

| 100ZDS100-32 | 100 | 32 | 1470 | 62 | 3.5 | 20 | γ≤1300 | 22 |

| 1300<γ≤1640 | 30 | |||||||

| 100ZDS100-45 | 100 | 45 | 1480 | 57 | 3.5 | 20 | γ≤1420 | 37 |

| 1420<γ≤1640 | 45 | |||||||

| 100ZGS100-60 | 100 | 60 | 1480 | 52 | 3.5 | 18 | γ≤1450 | 55 |

| 1450<γ≤1640 | 75 | |||||||

| 125ZDS150-20 | 150 | 20 | 1470 | 69 | 4 | 25 | γ≤1290 | 18.5 |

| 1290<γ≤1540 | 22 | |||||||

| 125ZDS160-30 | 160 | 30 | 1470 | 66 | 4 | 25 | γ≤1250 | 30 |

| 1480 | 1250<γ≤1550 | 37 | ||||||

| 125ZDS170-41 | 170 | 41 | 1480 | 65 | 4 | 25 | γ≤1280 | 45 |

| 1280<γ≤1560 | 55 | |||||||

| 150ZGS200-60 | 200 | 60 | 1480 | 64 | 4 | 25 | γ≤1220 | 75 |

| 1220<γ≤1460 | 90 | |||||||

| 150ZDS240-25 | 240 | 25 | 1480 | 70 | 4.2 | 30 | γ≤1320 | 37 |

| 1320<γ≤1640 | 45 | |||||||

| 150ZDS240-45 | 240 | 45 | 1480 | 68 | 4.2 | 27 | γ≤1440 | 75 |

| 1440<γ≤1640 | 90 | |||||||

| 175ZDS280-30 | 280 | 30 | 1480 | 70 | 4.5 | 30 | γ≤1390 | 55 |

| 1390<γ≤1640 | 75 | |||||||

| 175ZGS280-60 | 280 | 60 | 1480 | 66 | 4.5 | 27 | γ≤1320 | 110 |

| 1490 | 1320<γ≤1580 | 132 |

Related Products

Product Inquiry