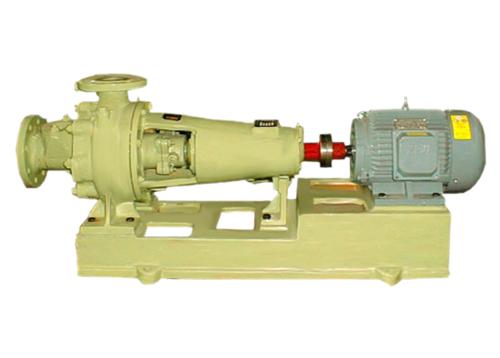

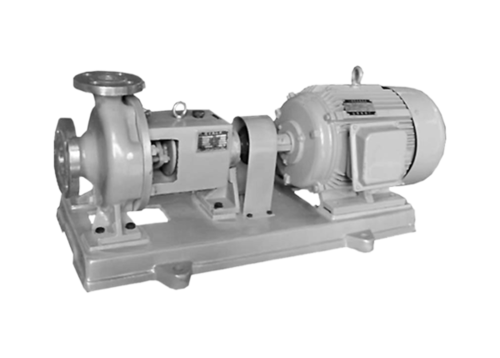

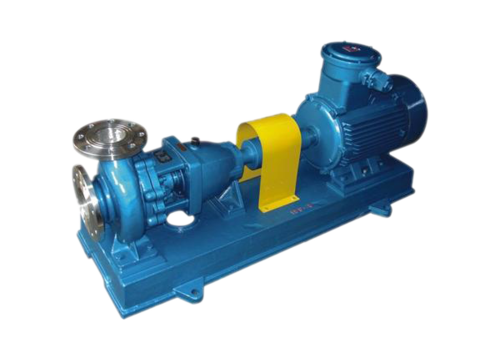

WZJ slurry pump

WZJ type corrosion-resistant non-clogging slurry pump, the impeller adopts double flow structure, strong passing capacity, strong anti-winding ability, high concentration of pulp delivery, mainly used for conveying a variety of pulp, sugar pulp, chemical slurry; suitable for metallurgy, coal, electric power, chemical industry, food and other departments of a variety of slurry and sewage treatment system.

Keywords:

Classification:

Inquiry Hotline:

WZJ slurry pump

I. Overview

The impeller of WZJ corrosion-resistant and non-clogging slurry pump adopts double-channel structure, which has strong passing ability, strong anti-winding ability and high pulp concentration, and is mainly used to transport various pulps, syrup and chemical slurry. It is suitable for various slurry and sewage treatment systems in metallurgy, coal, electric power, chemical industry, food and other departments.

II. Meaning of model

200 WZJ 210-27

| 200 | — |

Diameter of pump outlet200 (mm) |

| WZJ | — |

Non-clogging slurry pump |

| 210 | — |

Fluidity210(m3/h) |

| 27 | — | Head27(mm) |

Ⅲ、Performance parameters table

| Model | Flow | Head | Rotational Speed | Efficiency | Mating power (kW) | Necessary | Pump diameter (DN) | pass | |||

| Q | H | n | η | Specific gravity of liquidsγ | Cavitation allowance | Inhalation | Spit out | Particle diameter | |||

| m3/h | m | r/min | % | γ=1.0~1.1 | γ=1.2 | γ=1.5 | m | mm | mm | mm | |

| 65WZJ25-12 | 25 | 12 | 2840 | 58 | 2.2 | 2.2 | 3 | 3.7 | 80 | 65 | 20 |

| 65WZJ25-18 | 25 | 18 | 2870 | 57 | 3 | 3 | 4 | 3.7 | 80 | 65 | 20 |

| 65WZJ25-27 | 25 | 27 | 2900 | 55 | 5.5 | 5.5 | 7.5 | 3.7 | 80 | 65 | 20 |

| 65WZJ25-45 | 25 | 45 | 2930 | 50 | 11 | 11 | 11 | 3.7 | 80 | 65 | 20 |

| 80WZJ40-12 | 40 | 12 | 1440 | 62 | 3 | 3 | 4 | 3.9 | 100 | 80 | 28 |

| 80WZJ40-18 | 40 | 18 | 1440 | 61 | 5.5 | 5.5 | 7.5 | 3.9 | 100 | 80 | 28 |

| 80WZJ40-27 | 40 | 27 | 1450 | 58 | 7.5 | 7.5 | 11 | 3.9 | 100 | 80 | 28 |

| 80WZJ40-45 | 40 | 45 | 1460 | 54 | 15 | 15 | 18.5 | 3.9 | 100 | 80 | 28 |

| 100WZJ70-12 | 70 | 12 | 1440 | 67 | 5.5 | 5.5 | 7.5 | 4.2 | 150 | 100 | 28 |

| 100WZJ70-18 | 70 | 18 | 1450 | 66 | 7.5 | 7.5 | 11 | 4.2 | 150 | 100 | 28 |

| 100WZJ70-27 | 70 | 27 | 1460 | 62 | 11 | 15 | 15 | 4.2 | 150 | 100 | 28 |

| 100WZJ70-45 | 70 | 45 | 1470 | 57 | 22 | 22 | 30 | 4.2 | 150 | 100 | 28 |

| 150WZJ120-12 | 120 | 12 | 1450 | 70 | 7.5 | 11 | 11 | 4.7 | 200 | 150 | 30 |

| 150WZJ120-18 | 120 | 18 | 1460 | 68 | 15 | 15 | 18.5 | 4.7 | 200 | 150 | 30 |

| 150WZJ120-27 | 120 | 27 | 1470 | 65 | 18.5 | 18.5 | 30 | 4.7 | 200 | 150 | 30 |

| 150WZJ120-45 | 120 | 45 | 1470 | 60 | 30 | 37 | 45 | 4.7 | 200 | 150 | 30 |

| 150WZJ210-12 | 210 | 12 | 1460 | 73 | 15 | 15 | 18.5 | 5.2 | 200 | 150 | 30 |

| 150WZJ210-18 | 210 | 18 | 1470 | 72 | 22 | 22 | 30 | 5.2 | 200 | 150 | 30 |

| 150WZJ210-27 | 210 | 27 | 1480 | 70 | 30 | 37 | 45 | 5.2 | 200 | 150 | 30 |

| 150WZJ210-45 | 210 | 45 | 1480 | 66 | 55 | 55 | 75 | 5.2 | 200 | 150 | 30 |

| 200WZJ370-12 | 370 | 12 | 1470 | 74 | 22 | 30 | 30 | 5.7 | 250 | 200 | 40 |

| 200WZJ370-18 | 370 | 18 | 1480 | 73 | 37 | 37 | 45 | 5.7 | 250 | 200 | 40 |

| 200WZJ370-27 | 370 | 27 | 1480 | 72 | 55 | 55 | 75 | 5.7 | 250 | 200 | 40 |

| 200WZJ370-45 | 370 | 45 | 1480 | 70 | 90 | 90 | 132 | 5.7 | 250 | 200 | 40 |

| 250WZJ500-12 | 500 | 12 | 1470 | 75 | 30 | 37 | 45 | 6.4 | 300 | 250 | 45 |

| 250WZJ500-18 | 500 | 18 | 1480 | 75 | 45 | 55 | 75 | 6.4 | 300 | 250 | 45 |

| 250WZJ500-27 | 500 | 27 | 1480 | 74 | 75 | 75 | 90 | 6.4 | 300 | 250 | 45 |

| 250WZJ500-45 | 500 | 45 | 1480 | 73 | 110 | 132 | 160 | 6.4 | 300 | 250 | 45 |

Related Products

Product Inquiry