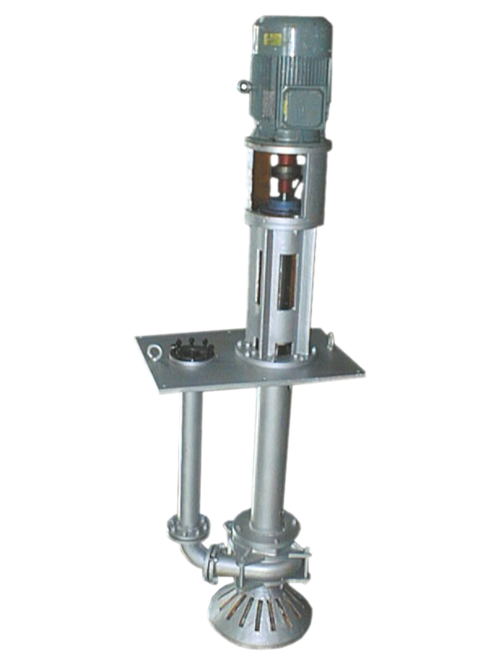

KBWL submerged pump

Keywords:

Classification:

Inquiry Hotline:

KBWL submerged pump

I. Overview

KBWL vertical submerged sewage slurry pump is used for conveying worn, corrosive or contaminated slurry liquids. The pump is submerged, so that the pump has no exhaust and start-up problems. The impeller is installed at the end of the cantilever shaft to keep the rolling bearing away from the liquid. According to the corrosion of the medium to the pump, the material of the parts in direct contact with the medium and corrosive gas is made of F5 alloy successfully researched by the Institute of Metal Research, Chinese Academy of Sciences and our factory, and can also be made of the materials required by users.

KBWL pump is suitable for chemical industry, petrochemical industry, mining, paper industry, cement plant, steel plant, waterworks, food and other industries, conveying various organic acids and inorganic acids, various alkaline solutions, salt solutions, and phosphate compound fertilizer plant slurry.

II. Meaning of model

65 KBWL 45 - 21(A)

| 65 | — |

Pump discharge caliber (mm) |

| KBWL | — |

KBWL lower chemical pump |

| 45 | — |

Flow rate (m3/h) |

| 21(A) | — |

Head: A is the head (m) when turning the impeller for the first time |

Ⅲ、Performance parameters table

| Model | Flow | Head |

Rotational Speed |

Efficiency | Necessary | Maximum transmission | Matching motor ( 1 ) | Matching motor ( 2 ) | ||

| Q | H | n | η | Cavitation allowance | Delivery particle size | Specific gravity of slurryγ |

Power |

Specific gravity of slurryγ |

Power |

|

| m3/h | m | r/min | % | m | mm | Kg/m3 | kW | Kg/m3 | kW | |

| 40KBWL15-15 | 15 | 15 | 2850 | 55 | 3.4 | 8 | γ≤1540 | 3 | 1540<γ≤1640 | 4 |

| 40KBWL15-25 | 15 | 25 | 2850 | 48 | 3 | 6 | γ≤1320 | 5.5 | 1320<γ≤1640 | 7.5 |

| 40KBWL15-40 | 15 | 40 | 2900 | 41 | 3.5 | 8 | γ≤1550 | 11 | 1550<γ≤1640 | 18.5 |

| 50KBWL30-20 | 30 | 20 | 2900 | 56 | 3.5 | 14 | γ≤1560 | 7.5 | 1560<γ≤1640 | 11 |

| 50KBWL30-30 | 30 | 30 | 2900 | 51 | 3.5 | 12 | γ≤1290 | 11 | 1290<γ≤1640 | 15 |

| 50KBWL30-45 | 30 | 45 | 2930 | 55 | 3.5 | 14 | γ≤1200 | 15 | 1200<γ≤1640 | 18.5 |

| 50KBWL36-60 | 36 | 60 | 2950 | 47 | 3.5 | 12 | γ≤1460 | 30 | 1460<γ≤1640 | 37 |

| 65KBWL45-21 | 45 | 21 | 1460 | 56 | 3.5 | 16 | γ≤1350 | 11 | 1350<γ≤1640 | 15 |

| 65KBWL45-30 | 45 | 30 | 1460 | 52 | 3.5 | 11 | γ≤1300 | 15 | 1300<γ≤1640 | 18.5 |

| 65KBWL50-40 | 50 | 40 | 1470 | 56 | 3.5 | 18 | γ≤1380 | 22 | 1380<γ≤1640 | 30 |

| 65KBWL54-60 | 54 | 60 | 1480 | 44 | 3.5 | 18 | γ≤1250 | 37 | 1250<γ≤1530 | 45 |

| 80KBWL80-21 | 80 | 21 | 1460 | 65 | 4 | 20 | γ≤1300 | 15 | 1300<γ≤1640 | 18.5 |

| 80KBWL80-30 | 80 | 30 | 1470 | 60 | 4 | 18 | γ≤1400 | 22 | 1400<γ≤1640 | 30 |

| 80KBWL80-40 | 80 | 40 | 1470 | 56 | 4 | 23 | γ≤1200 | 30 | 1200<γ≤1640 | 37 |

| 100KBWL100-20 | 100 | 20 | 1470 | 66 | 3.5 | 25 | γ≤1500 | 18.5 | 1500<γ≤1640 | 22 |

| 100KBWL100-32 | 100 | 32 | 1470 | 62 | 3.5 | 20 | γ≤1300 | 30 | 1300<γ≤1640 | 37 |

| 100KBWL100-45 | 100 | 45 | 1480 | 57 | 3.5 | 20 | γ≤1420 | 45 | 1420<γ≤1640 | 55 |

| 100KBWL100-60 | 100 | 60 | 1480 | 52 | 3.5 | 18 | γ≤1450 | 75 | 1450<γ≤1640 | 90 |

| 125KBWL150-20 | 150 | 20 | 1470 | 69 | 4 | 25 | γ≤1290 | 22 | 1290<γ≤1540 | 30 |

| 125KBWL160-30 | 160 | 30 | 1480 | 66 | 4 | 25 | γ≤1250 | 37 | 1250<γ≤1550 | 45 |

| 125KBWL170-41 | 170 | 41 | 1480 | 65 | 4 | 25 | γ≤1280 | 55 | 1280<γ≤1560 | 75 |

| 150KBWL200-60 | 200 | 60 | 1480 | 64 | 4 | 25 | γ≤1220 | 90 | 1220<γ≤1460 | 110 |

| 150KBWL240-25 | 240 | 25 | 1480 | 70 | 4.2 | 30 | γ≤1320 | 45 | 1320<γ≤1640 | 55 |

| 150KBWL240-45 | 240 | 45 | 1480 | 68 | 4.2 | 27 | γ≤1440 | 90 | 1440<γ≤1640 | 110 |

| 175KBWL280-30 | 280 | 30 | 1480 | 70 | 4.5 | 30 | γ≤1390 | 75 | 1390<γ≤1640 | 90 |

| 175KBWL280-60 | 280 | 60 | 1480 | 66 | 4.5 | 27 | γ≤1320 | 132 | 1320<γ≤1580 | 160 |

Related Products

Product Inquiry