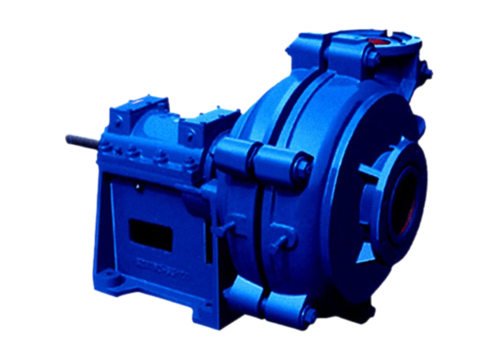

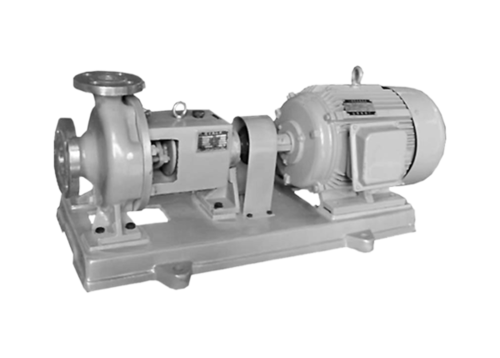

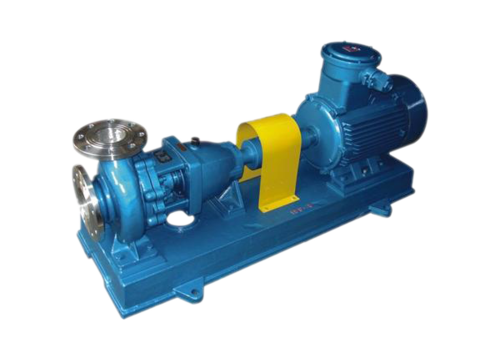

AH and HH slurry pumps

Keywords:

Classification:

Inquiry Hotline:

AH and HH slurry pumps

I. Overview

M, AH and HH are cantilever and horizontal centrifugal slurry pumps, which are suitable for conveying strong abrasion and high concentration slurry pumps in metallurgy, mining, coal, electric power, building materials and other industrial departments. This type of pump can be used in series in multiple stages.

The pump body of M and AH pumps has a replaceable wear-resistant metal lining. The impeller is made of wear-resistant metal or rubber. The inner lining and impeller of HH pump are only made of wear-resistant metal.The shaft seal of M, AH and HH pumps can be packing seal or centrifugal seal. The outlet position of the pump can be replaced by rotating eight different angles at 45º for installation and use as required.

II. Meaning of the model

10/8ST-AH(或M,HH)

| 10 | — |

Diameter of pump outlet (inch) |

| 8 | — |

Diameter of pump outlet (inch) |

| ST | — |

Bracket form |

| M、AH | — |

Slurry pump |

| HH | — |

High head slurry pump |

III. Introduction to Model

M, AH pump: For slurry with high concentration and strong abrasion, the flow rate is 40-80%

For slurry with medium concentration and medium abrasion, the flow rate ranges is 40-100%

For slurry with low concentration and low abrasion, the flow rate is 40-120%

HH pump: For slurry with medium concentration and medium abrasion, the flow rate is 40-80%

For slurry with low concentration and low abrasion, the flow rate is 40-100%

(The flow rate corresponding to the highest efficiency point at a certain speed is 100%)

IV. Performance parameters table (I)

| Model |

Maximum allowable power |

Material |

清水性能 |

Impeller |

|||||||

| (kW) | 护套 |

Impeller |

Flow rate |

Head H |

Revolving speed n |

Maximum efficiency |

Cavitation allowance |

叶片数 | 叶轮直径 | ||

| (m) | (r/min) | η(%) | m | ||||||||

| m3/h | l/s | (NPSH)r | |||||||||

| 1.5/1B-AH | 15 | M | M | 12.6~28.8 | 3.5~8 | 6~68 | 1200~3800 | 40 | 2~4 | 5 | 152 |

| RU | RU | 10.8~25.2 | 3~7 | 7~52 | 1400~3400 | 35 | 3 | ||||

| 1.5/1C-HH | 30 | M | M | 16.2~34.2 | 4.5~9.5 | 25~92 | 1400~2200 | 20 | 2~5.5 | 5 | 330 |

| 2/1.5B-AH | 15 | M | M | 32.4~72 | 9~20 | 6~58 | 1200~3200 | 45 | 3.5~8 | 5 | 184 |

| RU | RU | 25.2~54 | 7~15 | 5.5~41 | 1000~2600 | 50 | 2.5~5 | 178 | |||

| 3/2C-AH | 30 | M | M | 39.6~86.4 | 11~24 | 12~64 | 1300~2700 | 55 | 4~6 | 5 | 214 |

| RU | RU | 36~75.6 | 10~21 | 13~39 | 1300~2100 | 2~4 | 213 | ||||

| 3/2D-HH | 60 | M | M | 68.4~136.8 | 19~38 | 25~87 | 850~1400 | 47 | 3~7.5 | 5 | 457 |

| 4/3C-AH | 30 | M | M | 86.4~198 | 24~55 | 9~52 | 1000~2200 | 71 | 4~6 | 5 | 245 |

| 4/3D-AH | 60 | ||||||||||

| 4/3C-AH | 30 | RU | RU | 79.2~180 | 22-50 | 5-34.5 | 800-1800 | 59 | 3~5 | 5 | 245 |

| 4/3D-AH | 60 | ||||||||||

| 4/3C-AH | 30 | M | M | 97.2~194.4 | 27~54 | 9~53 | 1000~2200 | 55 | 3 | 240 | |

| 4/3D-AH | 60 | ||||||||||

| 4/3E-AH | 120 | M | M | 126~252 | 35~70 | 12~97 | 600~1400 | 50 | 2~5 | 5 | 508 |

| 6/4D-AH | 60 | M | M | 162~360 | 45~100 | 12~56 | 800~1550 | 65 | 5~8 | 5 | 365 |

| 6/4E-AH | 120 | ||||||||||

| 6/4D-AH | 60 | M | M | 180~396 | 50~110 | 7~61 | 600~1600 | 55 | 3~8 | 4 | 372 |

| 6/4E-AH | 120 | ||||||||||

| 6/4D-AH | 60 | RU | RU | 144~324 | 40~90 | 12~45 | 800~1350 | 65 | 3~5 | 5 | 365 |

| 6/4E-AH | 120 | ||||||||||

| 6/4D-AH | 60 | M | M | 144~324 | 40~90 | 10~52 | 800~1600 | 55 | 4.5~9 | 2 | 371 |

| 6/4E-AH | 120

Related Products Product Inquiry

| ||||||||||